+91-44-2524 0393

+91-44-2524 0393

Our scaffolding systems have high load-handling strength as well as are light in weight, sturdy, and cost-effective. They are manufactured from high-strength hot dip galvanized steel having a longer life span and dependability. The system allows for very quick installation at the construction site, easy transportation, and storage.

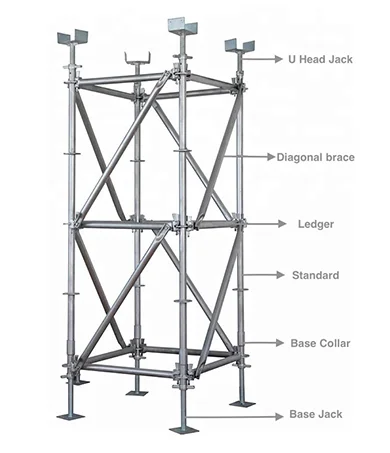

Ringlock systems are known for their versatility and efficiency. They employ vertical standards with pre-fabricated holes at regular intervals, allowing for easy and secure connections through horizontal ledgers and diagonal braces, all locked together with wedge-shaped locking rings. This system is prized for its speed of assembly and adaptability to various configurations

Cuplock systems are a widely used and efficient type of scaffolding system in the construction industry. They are characterized by their innovative design, featuring vertical standards with cup-like components that securely hold horizontal ledgers in place through a simple twisting action. This unique locking mechanism eliminates the need for nuts and bolts, making assembly and disassembly faster and more straightforward.

Scaffolding base jacks are essential components in the construction industry, providing a stable foundation for scaffolding structures. These adjustable devices are typically located at the bottom of scaffold legs and serve to level and stabilize the entire scaffold system. By turning the base jack's threaded rod, workers can raise or lower the scaffold to accommodate uneven terrain, ensuring safety and precision during construction or maintenance tasks.

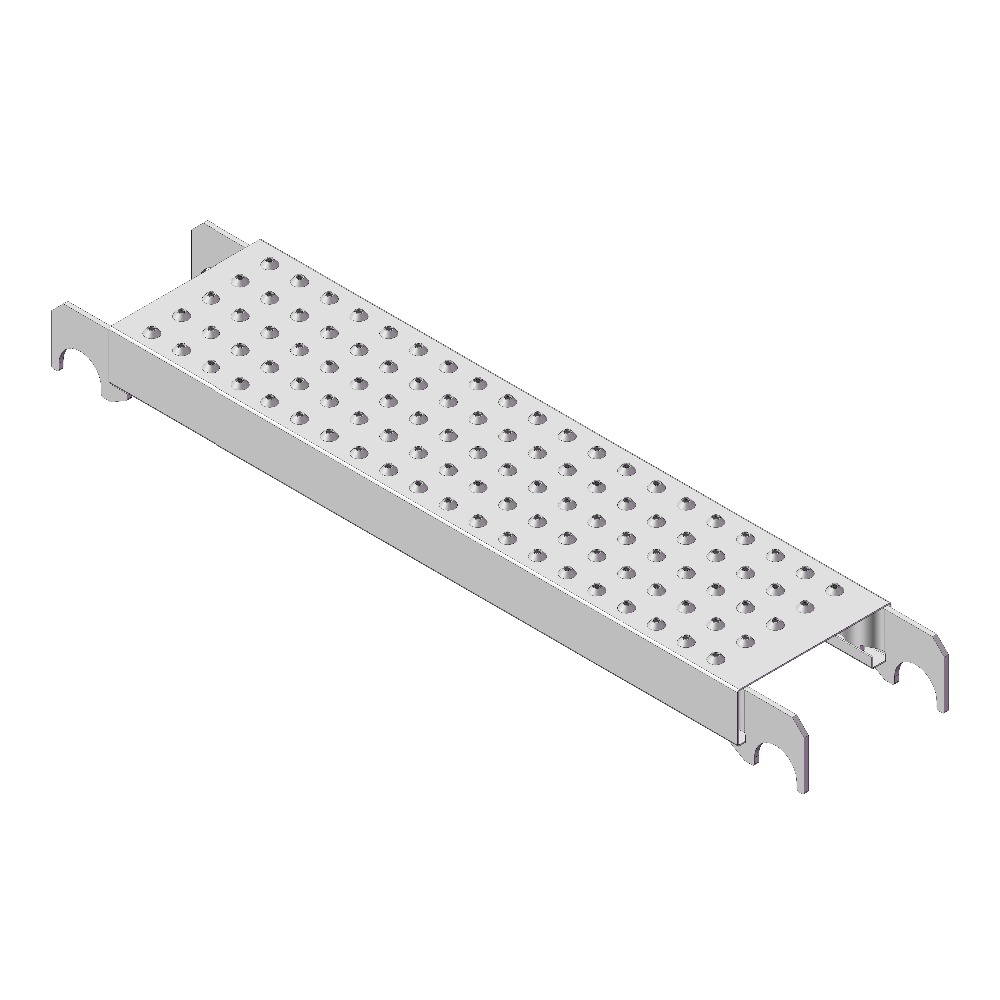

Scaffolding planks, also known as scaffolding footboards, are crucial components of scaffolding systems. They serve as sturdy walkways for construction workers, providing a safe and secure platform to access elevated work areas while distributing weight evenly. These planks are constructed from durable steel and are equipped with hooks that are securely riveted to the plank's ends. These hooks allow for easy and secure attachment to the scaffolding frames or cross braces.. Steel scaffolding planks come in various lengths and widths, making them adaptable to different scaffolding configurations. Their robust construction and non-slip surface enhance worker safety and efficiency on construction sites,

Shoring props are indispensable components in the construction industry, particularly for supporting heavy loads and providing stability during construction or renovation projects. These props are typically made of high-strength steel and are designed to be adjustable in height, allowing workers to customize their support to the exact requirements of the structure being worked on. Steel shoring props are known for their robustness and load-bearing capacity, making them suitable for a wide range of applications, from supporting concrete slabs and formwork to providing temporary support for beams and ceilings. Their durability, reliability, and ease of use make steel scaffolding shoring props an essential tool for ensuring safety and structural integrity on construction sites.

(In S235 and S355 material Grade)

SPM welding machine for standard

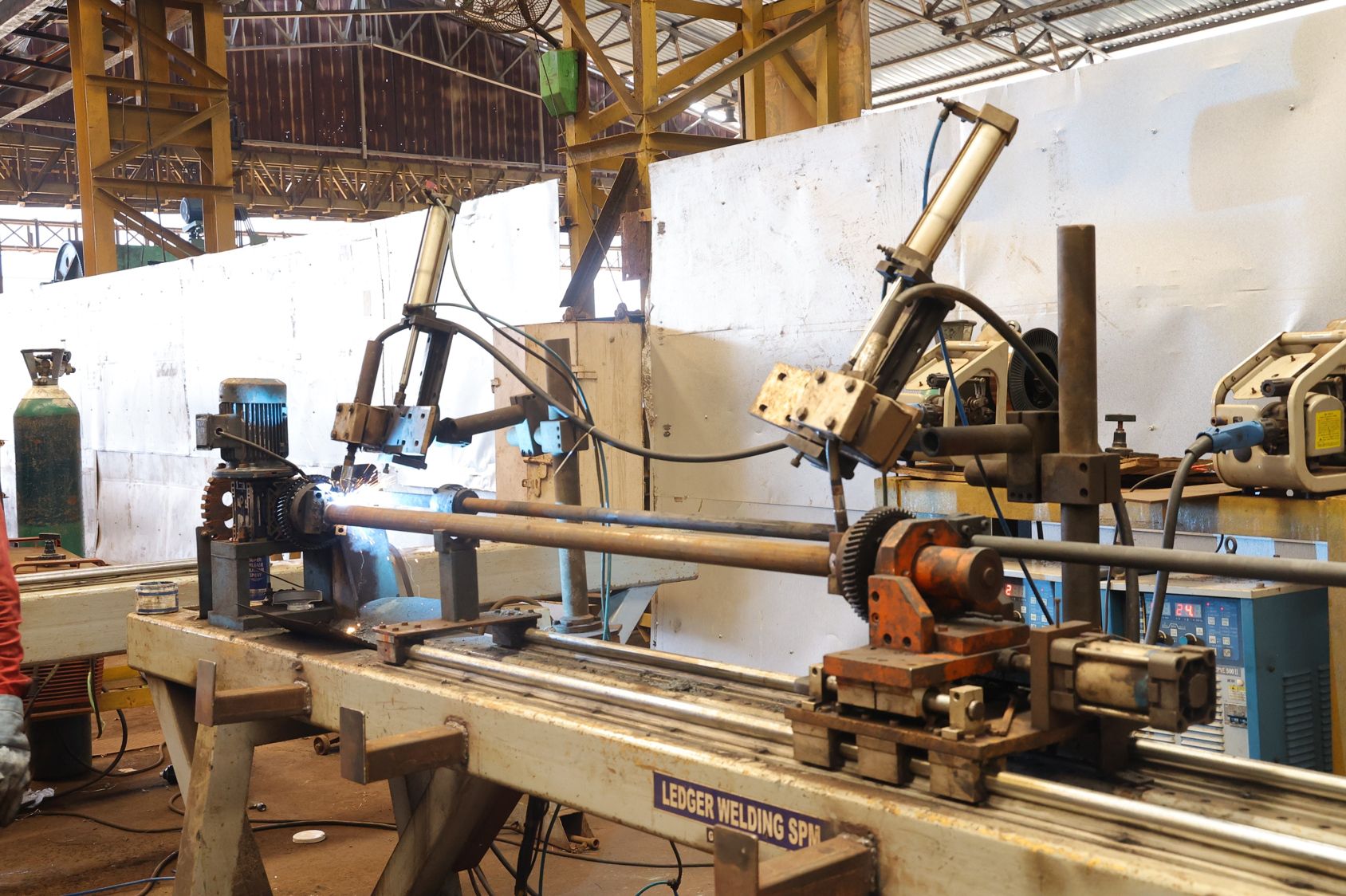

SPM Welding Machine for Ledger

Welding SPM for Base Jack